Paglalarawan ng Produkto

Magandang kalidad Metal Sheet at Tube Fiber Laser Cutting Machine Ginagamit sa Kagamitang Pang-agrikultura

Mga Tampok ng Produkto

Imported na high precision ball screw/rack at pinion transmission, high precision linear guide rail.

Imported servo motor driving system, imported helical gearbox.

Hiwalay na cutting tube device.

Mabilis na bilis ng pagputol, mataas na kahusayan, ligtas, matatag na pagganap.

Magandang kalidad ng Metal Sheet at Tube Fiber Laser Cutting Machine na Ginagamit sa Kagamitang Pang-agrikultura

Teknikal na data

| Power ng Laser | 500W-8000W (Opsyonal) |

| Working Area | 3000 * 1500mm |

| Kabuuang pagkonsumo ng kuryente | 10Kw<60Kw |

| Mode ng Paghahatid | Gear at Rack Double drive |

| Boltahe at Dalas | 380V 50Hz (60Hz) |

| Ang sukat | 4800*3260*1750mm |

Naaangkop na Mga Materyales

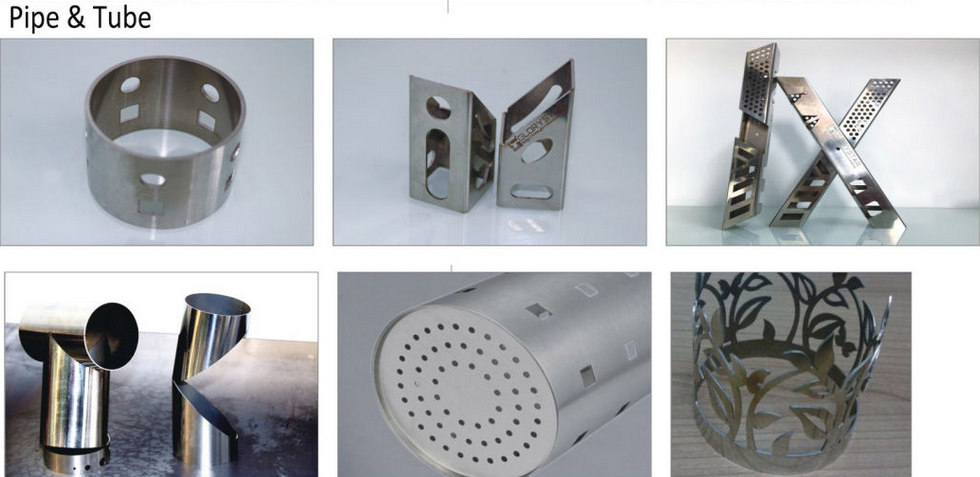

Pangunahing inilapat sa lahat ng uri ng mga sheet metal na materyales na may non-contact fast cutting, hollowing at pagsuntok. Tulad ng banayad na bakal, hindi kinakalawang na asero, haluang metal na bakal, manganese steel, galvanized, aluminyo, tanso at pagpoproseso ng metal pipe, atbp.

Naaangkop na Industriya

Malawakang ginagamit sa lahat ng uri ng mga industriya ng produktong metal tulad ng pagpoproseso ng sheet metal, kagamitan sa kusina at banyo, advertising at mga palatandaan, ilaw at hardware, mga de-koryenteng cabinet, mga piyesa ng sasakyan, makinarya at kagamitan, kagamitan sa sambahayan, elevator at precision parts processing, atbp.

Pangunahing Impormasyon

Laser Technology: Pagputol ng Fault ng Laser

Automation: Awtomatiko

Uri para sa Cutting Machine: Laser Cutting Machine

Uri: Metal Laser Cutting Machine

Uri ng Laser: Fiber Laser

Cutting Aurancy: 0.01mm

Kondisyon: Bago

Sertipikasyon: GS, Ce, ISO9001, SGS

Pamantayan: GB

Customized: Non-Customized

Materyal: Metal

Merkado: ACCURL

Transport Package: Seaworthy Plywood Case

Pagtutukoy: CE SGS FDA ISO

Pinagmulan: Anhui, China

HS Code: 8456100090

Halimbawang Palabas

| 1000W fiber laser cutting machine cutting parameters | |||||||

| Materyal | Pagputol ng kapal (mm) | Bilis ng pagputol(m/min) | Pagputol ng gas | Pagputol ng presyon | Nozzle | Collimator / Focus | Remarks |

| Carbon steel | 0.5 | 30-40 | Air | 6 | 1.5 solong layer | 75/125 | Mangyaring ayusin ang accord sa aktwal na focal position sa pamamagitan ng pagputol ng ulo, lahat ng mga parameter para sa sanggunian |

| 0.8 | 20-25 | Air | 8 | 1.5 solong layer | 75/125 | ||

| 1 | 18-22 | Air | 10 | 2.0 solong layer | 75/125 | ||

| 2 | 5-6.5 | Oxygen | 3.5 | 1.2 double layer | 75/125 | ||

| 3 | 3-3.5 | Oxygen | 0.5-1 | 1.2 double layer | 75/125 | ||

| 4 | 2-2.3 | Oxygen | 0.5 | 1.2 double layer | 75/125 | ||

| 5 | 1.5-1.8 | Oxygen | 0.5 | 1.2 double layer | 75/125 | ||

| 6 | 1.2-1.4 | Oxygen | 0.5 | 1.5 double layer | 75/125 | ||

| 8 | 0.9-1.2 | Oxygen | 0.5 | 2.0 double layer | 75/125 | ||

| 10 | 0.7-0.8 | Oxygen | 0.5 | 2.5 double layer | 75/125 | ||

| 12 | 0.5-0.65 | Oxygen | 0.5 | 2.5 double layer | 75/125 | ||

| Hindi kinakalawang na Bakal | 0.5 | 30-40 | Nitrogen | 7 | 1.5 solong layer | 75/125 | |

| 0.8 | 22-25 | Nitrogen | 10 | 1.5 solong layer | 75/125 | ||

| 1 | 20-23 | Nitrogen | 12 | 1.5 solong layer | 75/125 | ||

| 2 | 6-7 | Nitrogen | 15 | 2.0 solong layer | 75/125 | ||

| 3 | 2.5-2.8 | Nitrogen | 18 | 2.0 solong layer | 75/125 | ||

| 4 | 0.8-1.2 | Nitrogen | 18 | 2.0 solong layer | 75/125 | ||

| 5 | 0.6-0.8 | Nitrogen | 18 | 2.0 solong layer | 75/125 | ||

| Aluminyo | 0.5 | 20-25 | Hangin / Nitrogen | 8 | 1.5 solong layer | 75/125 | |

| 0.8 | 15-18 | Hangin / Nitrogen | 9 | 1.5 solong layer | 75/125 | ||

| 1 | 10-12 | Hangin / Nitrogen | 12 | 1.5 solong layer | 75/125 | ||

| 2 | 3-3.5 | Hangin / Nitrogen | 18 | 2.0 solong layer | 75/125 | ||

| 3 | 1-1.5 | Hangin / Nitrogen | 18 | 2.0 solong layer | 75/125 | ||

| Tanso | 0.5 | 22-30 | Nitrogen | 12 | 1.5 solong layer | 75/125 | |

| 0.8 | 13-17 | Nitrogen | 12 | 1.5 solong layer | 75/125 | ||

| 1 | 10-12 | Nitrogen | 15 | 1.5 solong layer | 75/125 | ||

| 2 | 2-3 | Nitrogen | 18 | 2.0 solong layer | 75/125 | ||

| 3 | 1-1.3 | Nitrogen | 18 | 2.0 solong layer | 75/125 | ||

| Copper | 0.5 | 15-18 | Oxygen | 12 | 1.5 solong layer | 75/125 | |

| 0.8 | 8-12 | Oxygen | 12 | 1.5 solong layer | 75/125 | ||

| 1 | 5-7 | Oxygen | 12 | 1.5 solong layer | 75/125 | ||

| 2 | 0.8-1.2 | Oxygen | 15 | 2.0 solong layer | 75/125 | ||