Paglalarawan ng Produkto

Product Application:

Furniture ,Medical Device,Fitness Equipment,Oil Exploration,Display Shelf,Farm Machinery,Bridge,Boating,Structure Parts.

Applicable type for tube:

Specially for round,square,rectangular,oval,waist round tube and other metal pipes

Naaangkop na Materyales:

Carbon Steel, Stainless Steel, Aluminum, Brass,Copper,Galvanized Steel.

Automatic Bundle Loader Steel Square Pipe Making Machine | |||

Pipe type | round, square, rectangular, oval, OB-type, C-type, D-type, triangle, etc (standard),Angle steel, channel steel, H-shape steel, L-shape steel, etc (option) | ||

Pipe length | 6000mm | ||

Pipe size | Φ20-200mm | ||

Ulitin ang kawastuhan ng posisyon | ± 0.03mm | ||

Katumpakan ng posisyon | ± 0.05mm | ||

Fiber laser source | 1000w/1200w/2000w/2500w/3000w | ||

Position speed | Max 90m/min | ||

Chuck rotate speed | Max 105r/min | ||

Pagpapabilis | 1.2g | ||

Cut Acceleration | 1g | ||

Bundle size | 800mm*800mm*6000mm | ||

Bundle weight | Max 2500kg | ||

Suplay ng kuryente | AC380V 50/60Hz 3PH | ||

Pangunahing Mga Tampok

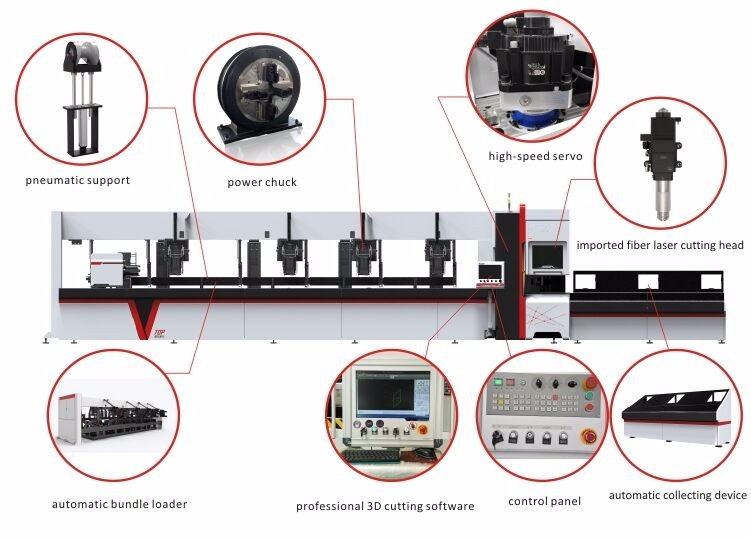

AUTOMATIC BUNDLE LOADER SYSTEM

1,Round pipe, rectangular pipe and other pipes can be fully automated loading, without human intervention. Other shapes pipe can be semi-automatic feeding artificially

2,Max loading bundle 800x800mm

3,Max loading bundle weight 2500kg

4,The total feed manipulator with frame and strand width control transport links in 2200mm, total height control in 2300mm, maximum height of not more than 2500mm. So overall into containers

5,The tape support frame for easy removal

6,Feeding robot body with a chain conveyor link structure integrated design, easy to debug transport

7,The pneumatic system components used AirTAC or other more high-end brand, PLC control, sensors and other selected Omron, Schneider and other well-known brands. Ensure the stability of the system and export standard

Detalyado

Parte ng makina

Name: Automatic loading mechanism

1.The total feed manipulator with frame and strand width control transport links in 2200mm, total height control in 2300mm, maximum height of not more than 2500mm. So overall into containers

2.Feeding robot body with a chain conveyor link structure integrated design, easy to debug transport

Parte ng makina

Name: Automatic collecting device

1.Automatic na pagtaas ng suporta, tumanggap ng tubo at mag-scrap sa basket

Ang suporta sa scale ng scale ay maaaring ayusin ang lapad ng suporta nang mabilis ayon sa diameter ng pipe

3.Visual scale naaangkop na suporta ng pag-angat ng aparato ay nakakatipid ng oras ng pagpapakain, tinitiyak ang concentricity, pinipigilan ang pag-swing ng pipe

Pangunahing Mga Tampok

Name: Power chuck

1.Cuck sa pamamagitan ng pagbabago ng landas ng gas, ang karaniwang apat na panga-link chuck, pag-optimize Cheng stroke power chuck doble kumikilos.

2. Paggawa ng iba't ibang mga diametro, ang hugis ng pipe sa saklaw ng paglalakbay (bilateral stroke 80mm), hindi na kailangang ayusin ang panga madaling pag-setup at nakasentro.

3.easy switching of different diameters, a substantial saving setup time..

Parte ng makina

Name: Pneumatic support

The cutting of pipes of different diameters, by adjustable support system to quickly and accurately find concentricity pipe and claw, to achieve rapid feeding, care feeding purposes, saving setup time cut-out.You can assist chuck support, reducing the swing pipe..

Pangunahing Mga Tampok

Name: Integration bed

1.As isang buong plate na welded bed, ang buong haba ng 8 metro.

2.Integration bed ay maaaring mas mahusay na matiyak ang concentricity ng mga kagamitan, patayo, tumpak na pag-install ng mabilis at mahusay.

3.The whole structure is compact precision

Mabilis na Mga Detalye

Kondisyon: Bago

Uri ng Laser: Fiber Laser

Naaangkop na Materyales: Metal

Cutting Thickness: Depends on power source

Pagputol ng Lugar: haba ng tubo 6m, 8m; diameter ng tubo 20-300mm

Cutting Speed: depending on materials and fiber power

CNC o Hindi: Oo

Mode ng Paglamig: Paglamig ng Tubig

Control Software: Cypcut

Suportadong Format ng Grapiko: AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

Lugar ng Pinagmulan: Anhui, China (Mainland)

Pangalan ng Tatak: ACCURL

Sertipikasyon: CE

Ibinigay ang Serbisyo pagkatapos ng benta: Magagamit ang mga inhinyero sa makinarya ng serbisyo sa ibang bansa

Model: P2060A

Repeat position accuracy: ±0.03mm

Position accuracy: ±0.05mm

Fiber laser source: 1000w/1200w/2000w/2500w/3000w

Position speed: Max 90m/min

Acceleration: 1.2g

Electric power supply: AC380V 50/60Hz 3PH